Stainless Steel Powder Sourcing & Technical Guide

This is also the topic that I have always wanted to talk about after touching powder in the industry for so many years—stainless steel powder (Stainless Steel Powder). It is the absolute “grain” of metal injection molding (MIM), additive manufacturing (AM/3D printing), and conventional powder metallurgy (PM). Austenitic grades (like 316L) and precipitation hardening grades (like 17-4PH) dominate the market today.

But I also found that most of the time, when the purchasing department is looking for materials, it is often only “unit price per kilogram.” This is actually a misunderstanding. According to the numerous production accidents I have dealt with, the particle shape determined by the pulverizing process (gas atomization or water atomization) and the oxygen content that directly affects the mechanical properties are the key to success or failure. Not to mention particle size distribution (PSD); 15-45μm for SLM and <22μm for MIM are completely different things. The wrong choice is the one mess of pores and surface roughness.

In this guide, let’s not talk about the truth but fill up these pits at one time from the selection of brands, the handling of suppliers, to some technical details of powder rheology.

Selecting the Right Stainless Steel Powder Grade

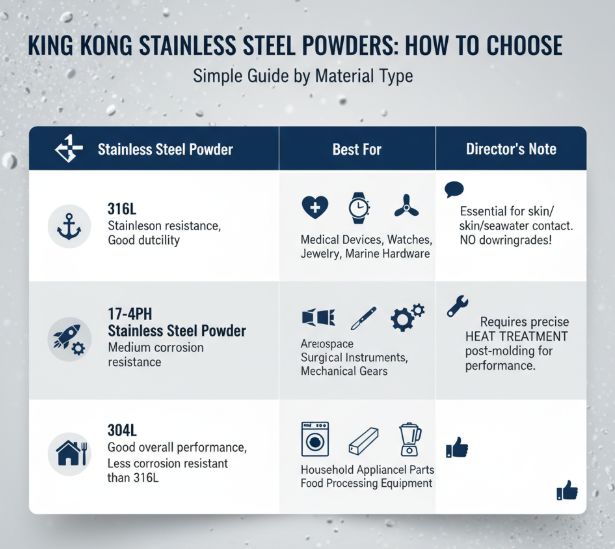

The three most common “King Kong” on the market—how to choose? I have clear suggestions:

316L Stainless Steel Powder (Industry Standard Configuration)

This is the world’s largest procurement of powder. It has excellent corrosion resistance and good ductility.

Best for: medical devices, watches, jewelry, and marine hardware.

Technical Director’s Note (Director’s Note): If your end product needs to contact human skin or seawater, don’t downgrade 304L to save money. In this application scenario, 316L is the bottom line, not negotiable.

17-4PH Stainless Steel Powder (High Strength Option)

This is the one precipitation hardening steel with high hardness and medium corrosion resistance.

Best for: aerospace components, surgical instruments, and mechanical gears.

Technical Director’s Note (Director’s Note): To buy this powder, you must understand the post-processing. Molding or printing is only the first step, and precise heat treatment can really “force” its performance; otherwise, it will be a waste of time.

304L Stainless Steel Powder (Cost-Effective Choice)

The overall performance is good, but the corrosion resistance is not as good as 316L.

Best for: household appliances, structural parts, and food processing equipment.

How to Evaluate Suppliers and Avoid Sourcing Traps

I have also seen many cases where the entire production line was shut down due to raw material batch problems. Checking according to the following list can save you a lot of trouble:

- Request oxygen content data: High oxygen content (> 1000ppm for some grades) directly causes parts to become brittle. A top powder factory will absolutely dare to put its control limits (Control limits) in front of you.

- Verification of atomization technology attribution: This is crucial. You want to make sure that the supplier has its own atomization tower. Many “traders” are used to mixing goods from different factories, which is a disaster for the stability we pursue at the production end.

- Check the packaging standard: Stainless steel powder is extremely damp. It must be confirmed that the supplier uses a vacuum-sealed aluminum foil bag with desiccant (usually 5kg, 10kg, or 25kg drum). If the packaging leaks, this barrel of powder is basically wasted.

Morphology and Production Processes

The manufacturing process determines what the powder looks like (morphology), and the morphology directly determines whether your machine can take it.

Aerosolized Powder (Gas Atomized) – Spherical

The molten steel is impinged with an inert gas (nitrogen or argon).

Features: Perfect spherical particles, extremely high fluidity, high bulk density (Packing Density).

Application: Required for 3D printing (SLM/EBM) and high-end MIM. The spherical powder can be spread evenly to ensure the uniformity of each layer.

Water-Atomized Powder (Water Atomized) – Irregular Shape

The high-pressure water jet is used to impact the molten steel.

Features: Irregular shape, like potatoes. The fluidity is poor, but the “green strength” (Green Strength) is higher, and the shape is better maintained when pressed.

Application: Traditional pressing and sintering (PM) process. The price is usually cheaper than aerosolized powder.

Particle Size Distribution (PSD) Selection Guide

The wrong particle size range is the number one cause of printer nozzle blockage or deformation of parts in the sintering furnace.

Reason Analysis of Recommended PSD Range for Application Process

- SLM / DMLS (laser 3D printing): 15-45 μm fine powder guarantees high resolution and smooth surface finish.

- EBM (electron beam melting): 45-105 μm coarse powder is to prevent the phenomenon of “smoking” (powder scattering) under electron beam bombardment.

- MIM (Metal Injection Molding): D90 < 22 μm requires ultrafine powder to mix with the binder and fill complex mold cavities.

- The high deposition rate of LMD (Laser Metal Deposition): 50-150 μm cladding requires larger particles.

Technical Director’s Hard Core Insight (Director’s Technical Insight): When looking at the TDS (technical data sheet), don’t just stare at the median diameter (D50). Be sure to pay attention to the values of D10 and D90. The narrower the distribution, the more consistent your printing or molding process. If the distribution is too wide, the fine powder will block the filter screen, and the coarse powder will cause incomplete fusion defects.

FAQs about Stainless Steel Powder

Q: Can I use MIM powder for 3D printing?

A: Not usually. MIM powders tend to be too fine (<22 μm) and lack flowability. In SLM printers, the scraper (recoater blades) cannot push such sticky powder at all, and the powder spreading will be very uneven. When placing an order, please be sure to explain your specific application process.

Q: How long is the shelf life of stainless steel powder?

A: If you keep the original vacuum-sealed packaging, putting it away for more than 2 years is no problem. However, once opened, it must be used up as soon as possible or stored in a moisture-proof cabinet with humidity control. It is important to note that oxidation is irreversible.

Author :Mark Harrison

I am Mark Harrison, a Senior Technical Director with over 9 years of hands-on experience in powder metallurgy (PM) and metal additive manufacturing (AM). Formerly the Head of R&D at a leading metal powder facility, I specialize in gas atomization processes and custom alloy development. Today, I help global manufacturers bridge the gap between complex material science and supply chain efficiency, ensuring you select the precise powder grade for your critical MIM and SLM applications.

ZM3DPowder

ZM3DPowder